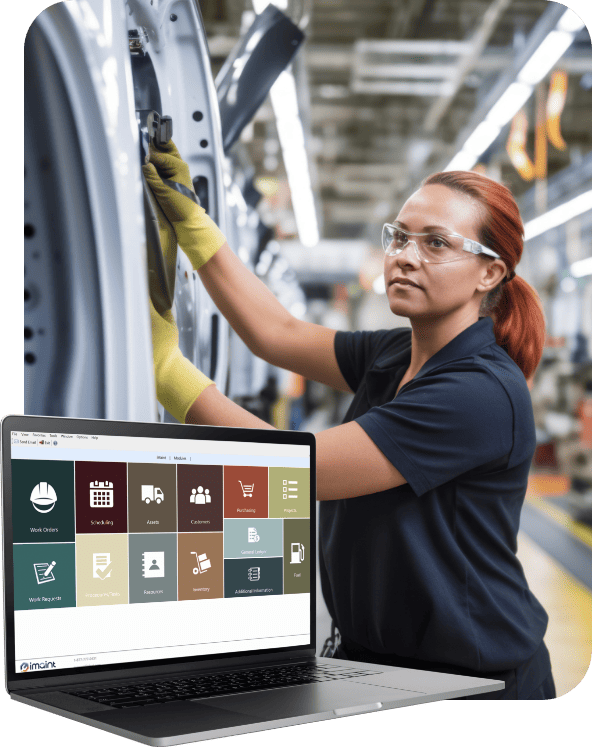

10 Advantages of Using Computerized Maintenance Management Software

Computerized maintenance management software has changed the face of maintenance…

Text goes here and is here for the text.Usually3 lines of text.

Text goes here and is here for the text.Usually3 lines of text.

Text goes here and is here for the text.Usually3 lines of text.

Text goes here and is here for the text.Usually3 lines of text.

Text goes here and is here for the text.Usually3 lines of text.

Text goes here and is here for the text.Usually3 lines of text.

Text goes here and is here for the text.Usually3 lines of text.

Text goes here and is here for the text.Usually3 lines of text.

Text goes here and is here for the text.Usually3 lines of text.

“The iMaint software is great but the customer support from DPSI is the best in the business. Every question I have had about this software over the last few years has been answered timely, explained thoroughly by a ‘real person’ who understands the product and isn’t just reading from a script. Everyone from DPSI has been a pleasure to work with!” – Steve M.

Enable non-licensed users to submit work or purchase requests

Access from any computer with network or Internet access

“The iMaint software is great but the customer support from DPSI is the best in the business. Every question I have had about this software over the last few years has been answered timely, explained thoroughly by a ‘real person’ who understands the product and isn’t just reading from a script. Everyone from DPSI has been a pleasure to work with!” – Steve M.

Capture information automatically through the course of normal events, minimizing manual entry. For example, when filling out work orders, iMaint captures history associated with every piece of equipment.

Customize iMaint for different levels of users. System administrator sees everything, but other users only see work modules relevant to their jobs. Users can also customize their view and save preferred settings.

Rename fields and labels according to company role in the marketplace and/or various maintenance activities

Choose from over 200 ready-to-run reports or create custom reports to track key performance indicators

iMaint caters to various industries like manufacturing and facilities. You can even combine within the same system.

Designate certain form fields as required to ensure that users are consistent in how they enter information.

iMaint puts your employees’ knowledge into a database, sharing it with various people in your organization.

Comply with regulatory requirements, increase safety, and reduce your vulnerability with the help of iMaint.

With iMaint, you can set different languages at each site according to needs.

Determine how your employees are doing on the job by evaluating their performance with iMaint.

Automatically reorder parts as needed—so you always have the right parts on hand.

iMaint maximizes equipment up time and keeps your equipment in peak operating condition.

Computerized maintenance management software has changed the face of maintenance…

All companies can benefit from maintenance control software today. CMMS…

Manufacturing CMMS software automates the process of maintaining assets to…

Dive into our CMMS software with our sales team to view user interface, features, options and customization abilities.