Managing Work Orders: What You Need to Know

Learn more about managing work orders in CMMS, work order…

Text goes here and is here for the text.Usually3 lines of text.

Text goes here and is here for the text.Usually3 lines of text.

Text goes here and is here for the text.Usually3 lines of text.

Text goes here and is here for the text.Usually3 lines of text.

Text goes here and is here for the text.Usually3 lines of text.

Text goes here and is here for the text.Usually3 lines of text.

Text goes here and is here for the text.Usually3 lines of text.

Text goes here and is here for the text.Usually3 lines of text.

Text goes here and is here for the text.Usually3 lines of text.

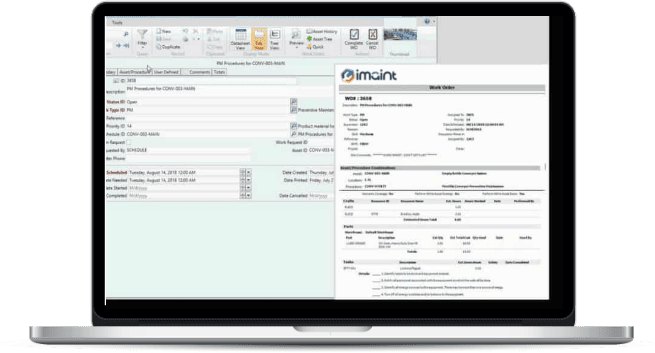

One vital aspect of an effective CMMS software package is work order management capabilities. Particularly with multi-site companies, the ability to have accurate inventory levels tied to the needs of a given asset and its potential upcoming maintenance is vital.

A well-developed work order management software package will also allow an organization to adequately forecast planned maintenance work orders, while allowing for unplanned work orders as well. This software will additionally schedule the completion of work orders in alignment with programmed priorities, in order to preserve operating capacity with minimal impact to the completion of customer expectations.

Managing work orders is not the full spectrum of services provided by CMMS software. Another key component is work order maintenance. Work order maintenance goes a step beyond tracking and prioritizing work orders, and begins to develop predictive patterns for maintenance.

An organization can set the parameters for this work order maintenance software based on a number of different triggers, including machine hours, a specific number of days, or a user-defined calendar. This level of customization gives an organization control of the maintenance process and allows for proactive responses to future maintenance needs, thereby reducing the need for reactive and panicked maintenance work orders.

A top-of-line CMMS package combines the capabilities of maintenance and management. This includes ensuring probability-based availability of repair and spare parts to facilitate the completion of any scheduled or unplanned maintenance work order.

Work order maintenance management software will do more than ensure parts are available. The costs of each individual part will be maintained, and reporting can be run at any level of detail required, ranging from cost centers to general ledger accounts to the costs associated with a specific part in one warehouse. Maintenance scheduling should be available by time or meter, based on priorities and valid days. Schedules should auto-generate and print as needed, including all necessary drawings, pictures, documents, procedures, and safety instructions for the accurate completion of the work order.

Bottom line – fully functioning work order maintenance management software gives an organization the insight needed to understand the impact of every asset and every current and future repair, at any time.

A general work order is any planned or unplanned maintenance task that isn’t considered a preventive maintenance, inspection, emergency, or corrective maintenance task. General work orders may include tasks like setting up or dismantling equipment, painting walls, or changing a light bulb, for example.

An inspection work order allows a maintenance technician to audit or inspect an asset based on a predetermined set of parameters. Inspections are usually time-based and associated with a specific schedule. During an inspection, any identified problems can be corrected with the creation of a new work order. Inspection work orders may be an important part of the audit trail for the asset.

A preventive maintenance work order handles any scheduled routine maintenance tasks performed on individual assets or groups of assets. Preventive maintenance is performed to prevent deterioration or failure on existing equipment in order to extend its lifespan. Preventive work orders define resource requirements, instructions, checklists, and notes for each task.

Preventive work orders should be associated with a schedule to ensure that the maintenance task is performed at a specific time interval, such as every 180 days, or in the case of fleet maintenance, after a set number of miles. Any equipment that is essential for your organization should be included in your preventive work order schedule in order to provide continuous production

An emergency work order is generated when an asset breakdown occurs and needs to be repaired immediately. This type of work order records and tracks any reactive work performed that was not planned. Once the work is complete, it is important that the maintenance technician provide information in the work order about what happened, why the breakdown occurred, what was done about it, and what can be done to prevent it from occurring again, thus adding valuable information to the history of the asset.

A corrective maintenance work order is generated when a maintenance technician discovers a problem while completing a preventive maintenance, inspection, general, or emergency work order. Corrective maintenance is performed to identify, isolate, and rectify a fault so that the equipment, machine, or system can be restored to its best working condition. Unlike an emergency work order, a corrective maintenance work order is planned and scheduled because the problem or issue was identified before a failure occurred. A corrective maintenance work order may cover the repair, restoration, and/or replacement of equipment.

Ideally, maintenance technicians will close work orders 24 hours within completing a job. This will help ensure that the information in the system remains current. It’s essential for maintenance technicians to use CMMS software to record adequate closeout data on work orders. Information about the work performed and lessons learned should become part of your maintenance records.

Learn more about managing work orders in CMMS, work order…

Every organization has a maintenance workflow process. When it’s undocumented,…

Utilize software for managing work orders to simplify and control…

Dive into our CMMS software with our sales team to view user interface, features, options and customization abilities.