Key performance indicators (KPIs) are crucial for measuring the success of your maintenance operations. Without real-time data displayed on an easy-to-read dashboard, you risk missing important trends and potential issues. Choosing the right KPIs to include on your CMMS (computerized maintenance management software) dashboard is vital for continuous improvement. Here are the top KPIs you should include to maximize the effectiveness of your maintenance management.

1. Top 10 Maintenance Costs

Tracking the top 10 maintenance costs helps you identify which pieces of equipment are the most expensive to maintain. This KPI gives management the insights needed to decide whether to continue maintaining an asset or consider replacement. By understanding where you’re spending the most, you can also budget more effectively for future maintenance costs in those areas.

2. Mean Time to Repair (MTTR)

MTTR measures the mean time it takes to repair an asset after it fails. To calculate MTTR, divide the total downtime by the number of breakdowns. This KPI helps you gauge the difficulty of performing maintenance on an asset and assess the efficiency of your response. By tracking MTTR, you can determine if your maintenance efforts are improving over time.

3. Mean Time Between Failure (MTBF)

MTBF tracks the mean time an asset operates before it fails and needs repairs. Calculate this KPI by dividing the total uptime by the number of breakdowns. Monitoring MTBF helps you identify problematic assets and take proactive steps to improve their reliability.

4. Labor Estimate vs. Actual

Comparing labor estimates to actual labor usage shows whether you’re overestimating or underestimating labor needs. This KPI helps you refine your scheduling and better predict future labor requirements. Accurate labor forecasting leads to more efficient maintenance operations and resource allocation.

5. Maintenance Backlog

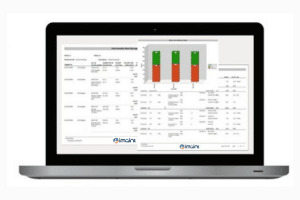

Maintenance backlog refers to work that needs to be completed, which could stem from safety concerns, preventive maintenance and other factors. There are multiple KPIs you can track to keep tabs on maintenance backlog, including:

Work Order Backlog by Work Type

The maintenance backlog includes work that still needs completion, often due to safety concerns, preventive maintenance, or other factors. Track various KPIs within the backlog, such as:

- Work Order Backlog by Work Type: Use graphs to see which work orders—whether preventive, corrective, or project-related—are taking the most time to complete. This information helps management troubleshoot problems, adjust plans, and prioritize tasks more effectively.

Why Tracking KPIs on CMMS Dashboards Matters

Using KPIs to measure effectiveness empowers companies to make more informed decisions. CMMS software products often provide dashboards that display these KPIs on a central screen, visually representing operational data with charts and gauges. While the general KPIs mentioned here are essential, consider customizing performance indicators to address your organization’s specific maintenance challenges.

Take Control of Your Maintenance with the Right KPIs

Incorporating these essential KPIs into your CMMS dashboard helps you optimize maintenance operations and improve overall performance. Contact DPSI to discuss your maintenance goals, identify specific KPIs to include on your CMMS dashboard, and explore how other features can help you achieve your objectives.